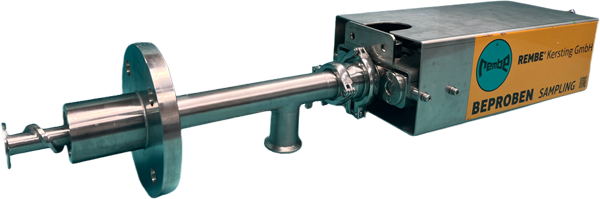

Screw sampler

A screw sampler (also called a screw sampler) is used to sample bulk material and has specific applications that distinguish it from other sampling methods such as cup or piston samplers. The choice of the appropriate sampler depends on the type of bulk material, the sampling objectives and the practical requirements. Here are some reasons why and when a screw sampler might be preferred over other types:

Screw sampler

- Type of material: Screw samplers are particularly suitable for granular or powdery bulk materials that can easily bridge or clump together.

- Continuous sampling: Screw samplers can be used for continuous sampling, where the material is constantly sampled over a period of time.

- Automation: They can be integrated with automated sampling systems, making sampling efficient and consistent.

- Reduction of clumping and bridging: The screw movement helps to prevent clumping or bridging in the bulk material, which could be a problem with fine-grained materials.

Cup or piston samplers

- Simple materials: These work well for coarse-grained or free-flowing materials where there is less risk of clumping or bridging.

- Simplicity: Cup and piston samplers tend to be simpler and more cost-effective, suitable for manual or less complex automated systems.

- Representative sampling: In some cases, cup or flask samplers may be better suited to take representative samples from a bulk stream, especially if the material is heterogeneous.

Result

The choice of a screw sampler over other types depends on the specific requirements and objectives of the sampling. If the material is fine-grained or prone to clumping, if continuous sampling is required, or if a high degree of automation is desired, a screw sampler might be the best choice. Otherwise, simpler cup or piston samplers may be more suitable, depending on the application.